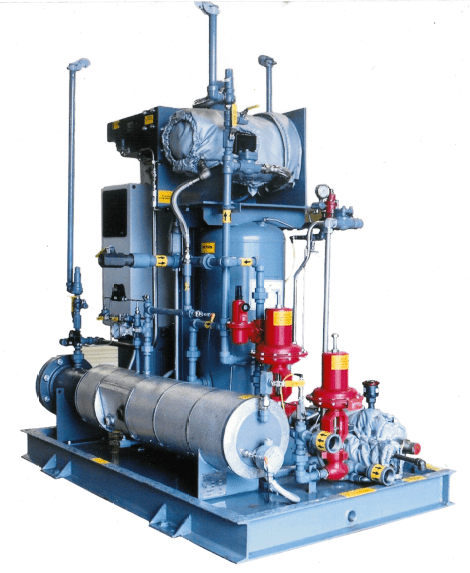

ERU-WG-15 (Patent no U.S. 12, 303, 815)

Designed specifically for "wet gas" applications (up to 2500 Btu per CF)

Encapsulated scroll compressor

15 Horsepower system, 3-phase 460V

Flow capabilities of 1500 Scf/Hour

Discharge pressures to 160 Psig

NEC Class I, Division II rated

PLC controller & VFD included

Gas/oil stabilizer system for wet-saturated gas streams

Packing Emission Recovery Units for Wet Gas Applications

The EPA has recognized the issue of fugitive emissions emitted from compressor packing boxes, gas operated control valves, and pumps contribute up to 72.4 BCF of methane per year into the atmosphere. All packing systems leak under normal conditions. Continued servicing, packing replacement, or flaring of these gas emissions is costly and not a total solution. The TESCORP VentMaster ERU recovers and returns these gases back to the process through a simple and affordable process.

- Eliminate Costly Fugitive Emissions in wet gas applications

- Stay in Compliance with EPA Mandates

- Reduce Service Expenses

Packing Emission Recovery Unit Features

TESCORP has designed, tested, and is manufacturing a standard “gas vapor emissions recovery system” for use with existing gas compression systems and gas-operated components

The "Ventmaster ERU" addresses the issue of leaking piston rod packing systems by:

- Recovering the gas from the compressor packing box by utilizing the ERU capacity controls to maintain a positive pressure in the packing case. The vapors are then evacuated by the TESCORP ERU that produces a slight vacuum as necessary to capture and transport all leaking emissions.

- The recovered gas is then pressurized to meet the existing pressures necessary to re-enter either the first stage of compression or the compressor fuel gas system for utilization in the current process.

- The TESCORP “ERU” system is capable of capacities of 1250 scfh and discharge pressures of up to 160 psig.

This system allows existing dry gas pipeline compressor systems to meet the requirements for compliance to EPA “New Source Performance Standards” (40 CFR 60 Subpart 0000a).

Designed and constructed as a complete system for ease of installation and operation, systems are complete with:

- Encapsulated 15 horsepower compressor unit without packing or seals to leak

- 3-Phase/460VAC VFD with controller for totally automatic operation and capacity control

- NEC Class I, Division II controls with customer interface and local fault annunciation

- Inlet receiver with condensate blow-case for removal and elimination of produced condensates

- Compact design with only a 4’ x 4’ footprint for ease of installation & utilization of space

- Gas after-cooling of discharge gas for reinjection into either 1st stage of compression or into the compressor fuel gas system

- Weather-proof enclosure available as option